|

The FilmStar DESIGN Free Version is a powerful implementation with fixed

indices. It may be all that is

required for your purposes. |

|

FilmStar

Optical Thin Film Software is a

suite of Windows programs for designing, manufacturing, and

measuring optical coatings. Coatings are applied to

glass and other surfaces by high vacuum deposition. FilmStar is

distinguished by its ease-of-use and connectivity to deposition monitors and spectrophotometers. FilmStar stands alone in the ability

of its users to customize and automate. |

|

Scantraq is

a standalone version of FilmStar MEASURE,

marketed to chemists and spectroscopists and supporting UV/Vis/IR data

acquisition and analysis from current and legacy PerkinElmer and other models. With its built-in development tools, Scantraq provides a

powerful alternative to the software supplied by instrument

manufacturers. Agilent (HP) 8453 users may be surprised to know that serial (USB) is

supported.

|

|

Too high: lose

order.

Too low:

lose money. |

|

Take the

QC Highway to Higher Yields

Saving %R and %T

spectra? Insufficient! You must also save info about each curve in order to sort,

select, analyze and improve. After all, you can't plot Y vs. X if you only know

Y. We make it easy with

FilmStar Database code and

online support far beyond that provided by instrument manufacturers. And if

you're too busy to adapt our sample source code we'll do it for you!

Do you have tens of thousands of files in a Spectra directory? In the FilmStar Database,

that's one file to back-up, sort, search and analyze,

thereby meeting ISO-9000

goals and security requirements.

Set the

Right Price

BBAR EXAMPLE 1: You've been

delivering AR coatings averaging <1.0%

and your customer now requires <0.5%. What's the correct new price?

Try for yourself!

(Write access to C:\Windows\Temp required.)

FileMaker 45 Day

FREE TRIAL Windows 10/11

BBAR_Demo.fmp12 BBAR

database file

QA_Demo.xlsm Excel BBAR % yield calculator

Want a preview before downloading?

Watch our

YouTube (1 minute, no audio) or

contact us for a

ZOOM demo.

BBAR EXAMPLE 2: Assume maximum <0.5% and average <0.25%.

Which technician deserves a pay raise? |

|

|

|

Society of Vacuum Coaters TechCon 2021

Specifying n&k in

Optical

Thin Film Calculations

PowerPoint

YouTube

Click here for help extracting n&k from %T and %R

spectra.

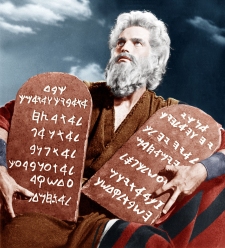

Wondering about #11? Thou shalt have more targets

than wiggles. |

|

|

Webb

Space Telescope Mirror

We started using these

(USA domestic) stamps after learning that FilmStar was

utilized in characterizing the mirror's gold coating.

As it's rare to

find

stamps related to optical coatings and fearing

they will eventually be discontinued, we recently

bought 100 more.

Maybe not rare? Our international letters get a round

flower stamp, currently the

African Daisy which has an

iridescent purple center. |

|

|

Filter Buyers Demand Excel QA Reports

In the

'good old days', an acceptable quality assurance report was

a

strip-chart trace stamped

PASSED

.

Filter buyers now require Excel reports as in this

FREE EXAMPLE derived

from FTG automation solutions. Of course, you're not

limited to bandpass designs;

e-mail or call +1 609-924-6222 to discuss your

requirements. |

|

|

StellarNet Support

Lots of

parts? Why scan with a

slow double-beam spectrophotometer if an inexpensive near-instant diode-array

instrument meets requirements? And what about optics too large for

sample compartments?

Our StellarNet Server simplifies

operation and supports MEASURE

as well as 32/64-bit Excel. EVERYONE has Excel; there's

no better way to distribute QA results.

And when you do need that slow high resolution

double-beam instrument like PE Lambda or Agilent

Cary, you are able to use the same MEASURE

software: one software, many instruments.

Click here

to learn more and

contact us to discuss QA procedures and automation

solutions. |

|

|

|

Chocolate Chip Cookie

Quality Assurance Procedure

Taste one and you can assume they're all

good. But that doesn't apply to optical coatings when protocols demand 100% inspection! As manual QA is slow and

error-prone, you need to automate procedures and reports as in our

Bandpass and

Edge Filter Excel workbooks.

PerkinElmer and Agilent can't help you, but

we can with

FilmStar MEASURE.

E-mail

or call +1 609-924-6222 today to discuss requirements and arrange your

personal webinar. MEASURE supports PE Lambda/FTIR, Cary

UMA,

Pike autosamplers,

Nicolet FTIR,

OOI,

temperature

controllers, etc.

Do it yourself (it's not string theory) or request a turnkey FTG

solution. |

|

|

|

Coating Both Sides

Extinguishing the flame, cooling, reheating and grilling the

second side is clearly NOT an option for burgers.

But when coating optics on both sides, you do have two options:

A. Two pump-downs, B. Single pump-down with

a flip fixture. The economics are simple: PHDCPHDC vs. PHDDC (Pump Heat Deposit Cool).

The Option B strategy requires

coating software that predicts %R or %T as a function

of layer thickness while flipping the optic.

Click here

to see how it's done. It's a bit tricky, so read

carefully and/or contact us for an interactive online

explanation.

|

|

Click to Pay links:

Contact FTG Software

This site

can also be accessed via

www.ThinFilmSoftware.com

|